How Disassemble a Thread Tensioner

You are having problems with thread tension on your sewing machine? Thread tension in stitches is very tight or loose? Sometimes to fix this problem is needed to remove a tensioner and clean it.

Here you will to learn how to fix a tension problems of needle and bobbin thread.

You have tightened a thread with a control tension dial as far as it will go, but the thread is still loose and bunching up ? You have tried many ways to fix this problem but unsuccessfully.

In this case you need try to remove the tensioner with sewing machine body and disassemble it.

Note: Sometimes to fix this problem is enough to clean a tensioner (between discs) from dust, thread scraps etc.

It is easiest to disassemble and clean a tensioner of old sewing machines models.

To remove the tensioner you need first remove a faceplate from front part of sewing machine.

How to remove a thread tensioner

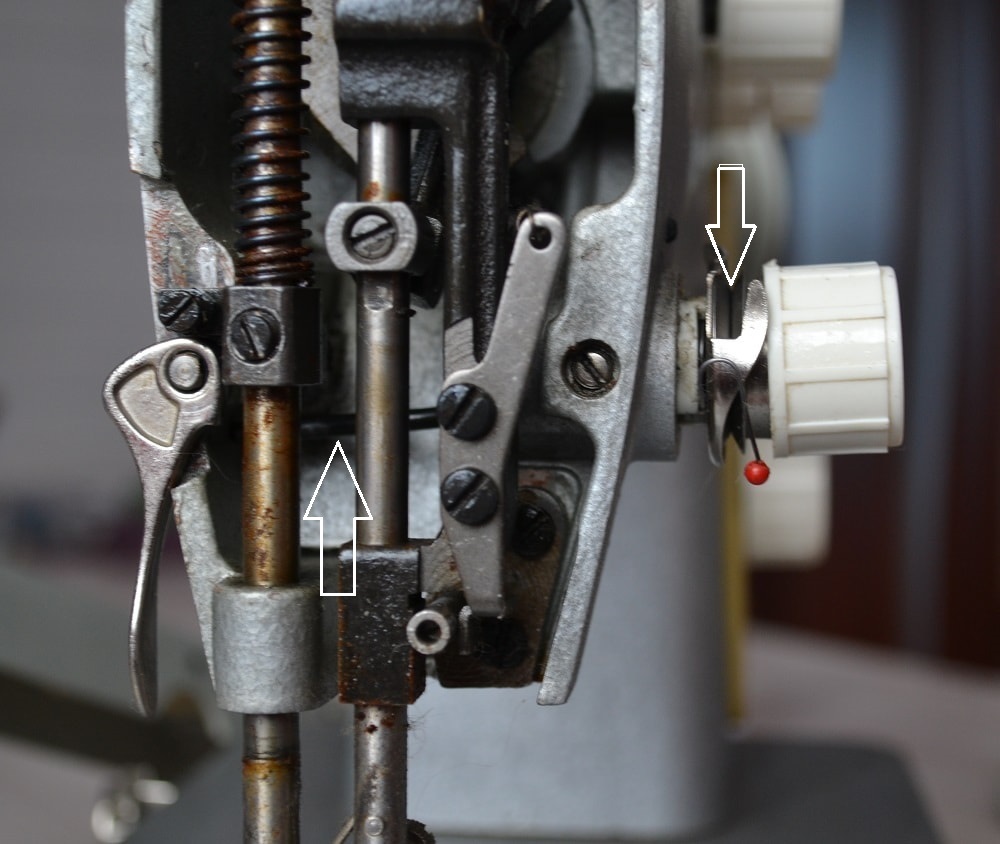

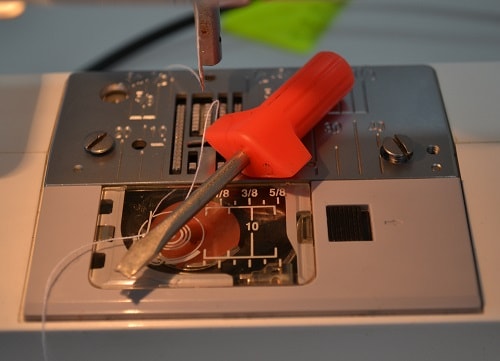

Look at this photo. These two arrows indicate details affecting on needle thread tension.

Lift up a presser bar lifter (lever). In this position both tension discs should not push top thread and vice versa.

You rotate tensioner dial but thread tension does not change at all ? In this case need loosen a set screw and pull out the tension assembly.

Take off the thread tension assembly. Grip it with fingers and pull towards you.

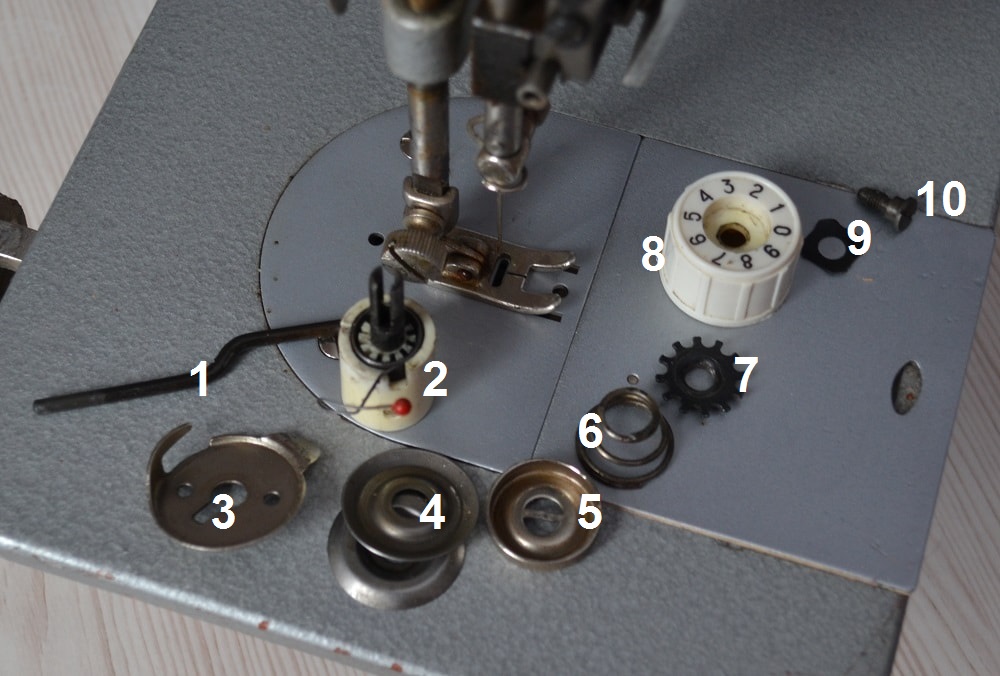

Parts of thread tensioner of old sewing machine

The first thing what to do you is marking assembly sequence. Some models of sewing machines have some features. If you have no manual with scheme you must be sure of how it goes back together.

Clean machine area of tensioner first and all parts in order they go back on.

Thread Tensioner of Your Sewing Machine. How to Adjust Thread Tension.

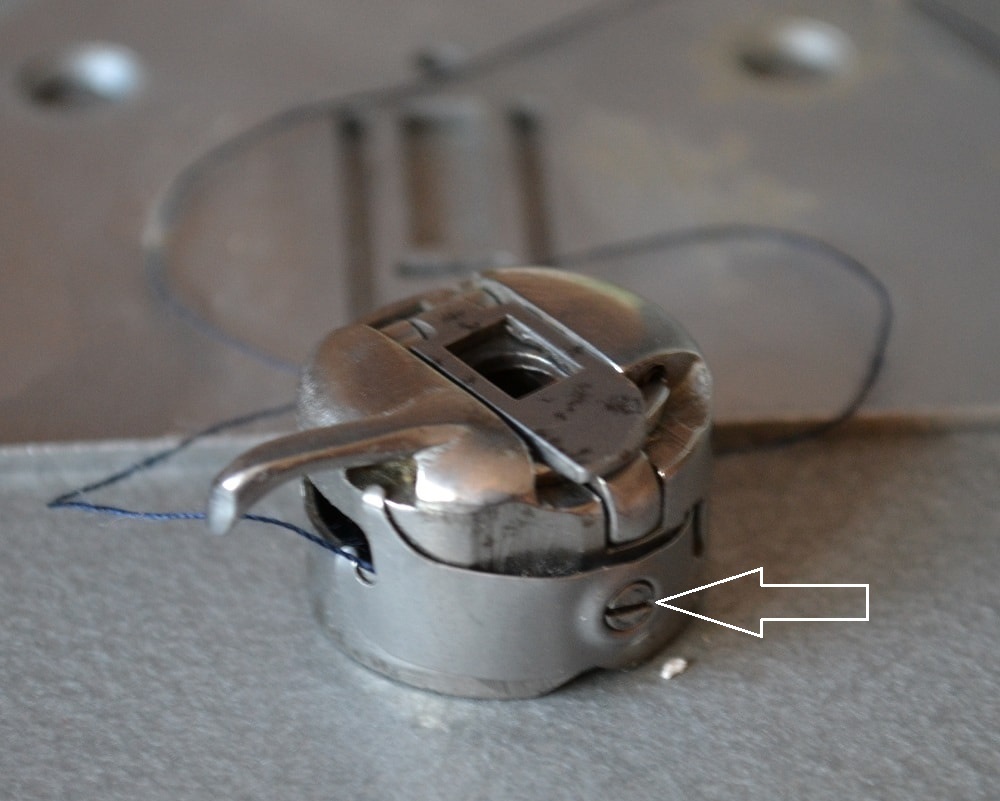

How to adjust a bobbin thread tension

Check tension of bobbin thread. When it is very weak or nery strong learn here how to change it.

To increase the tension a bobbin thread you need turn this smll screw clockwise and vice versa.

Sew a few probe stitches. If you still have thread bunching up on bottom side of fabric you need to check other parameters of working the sewing machine.

Inspect sewing machine needle with a magnifying glass first. If needle tip is blunt remove it away and set a new needle.

Make sure that thread are insert between the tension discs correct.

Sometimes is needed to change type of sewing thread, etc.

Troubleshooting Thread Tension Sewing Machines

If you have thread tension problems, here you find tips on how to fix many of them.

Tips for Using your Sewing Machine

Here you find top tips and tricks how to use your sewing machine.

Tips for Using your Serger

If you have an overlock sewing machine you need learn these tips how to use a serger.

How to Clean and Oil a Sewing Machine

Your sewing machine works very noisy? In this case you need to clean and oil sewing machine. Here are the oiling and cleaning instructions.

How to use the coverstitch machine

The coverstitch machine is most used for sewing the clothing made from knit jersey fabrics. Here you find a tutorial how to use the coverstitch machine.

Tips for Choosing a Sewing Machine

How to choose your first sewing machine. A few key features of sewing machines you need to know necessarily.

How to Sew a Button by Hand

Learn how to sew a flat button having two or four holes. For the big size buttons need use a method of sewing on buttons "on the leg".

How a Sewing Machine Works

Learn how works a sewing machine. Here is home model of the zigzag sewing machine.